Unbeatable benchmark for flip chip assembly equipmentįLIPJET FJ520-ULTRASONIC FLIPCHIP BONDER The Flipjet FJ520 is the latest evolution of the Hesse GmbH flipchip bonder platform. Matching the requirements of IDMs and subcons (90% market share). Field-proven, reliable machine concept and production process. No restriction on substrate type (lead frames, strips, panels, wafers). Capability to handle any flip chip size. Operator-independent quality by fully automatic machine calibration.

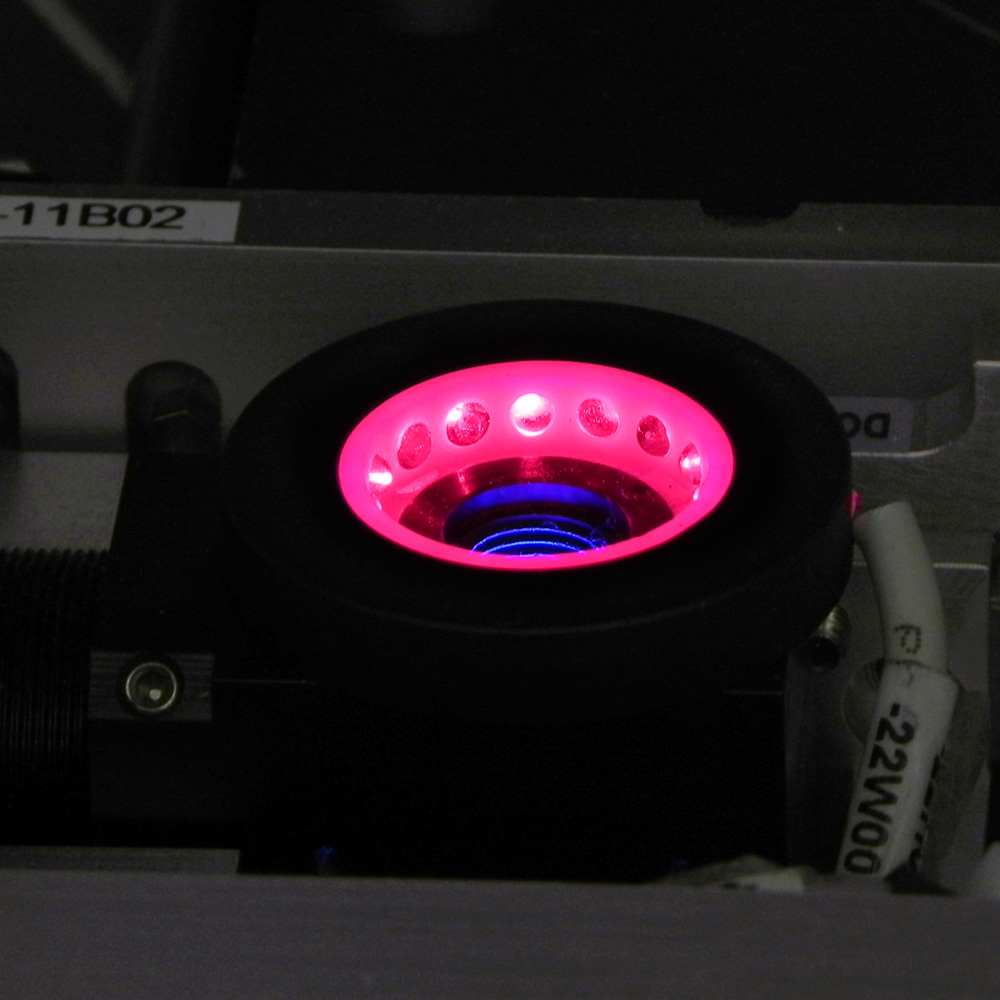

Exceptional accuracy of ± 10µm 3 Sigma at highest speed. Beside the factory-proven QUANTUM values it provides superior speed and accuracy while drastically improving your cost-of-ownership Reliable and accurate flip chip processĭATACON 8800 FC QUANTUM SIGMA The Datacon 8800 FC QUANTUM sigma flip chip bonder represents the next generation of the high-volume, high-accuracy 8800 platform. Operator independent results ensured by auto calibration. Full recipe transfer from machine to machine. Load recipe from host and run on any machine. Innovative parallel activity machine design with Phi-Y movement pick-and-place. Low vibrations – no time wasted for motion settling. Simultaneous movement of chip and camera – no time wasted for image taking.

Exceptional accuracy of ± 10µm 3 Sigma at highest speed. Beside the factory-proven QUANTUM values it provides superior speed and accuracy while drastically improving your cost-of-ownership Reliable and accurate flip chip processĭATACON 8800 FC QUANTUM SIGMA The Datacon 8800 FC QUANTUM sigma flip chip bonder represents the next generation of the high-volume, high-accuracy 8800 platform. Operator independent results ensured by auto calibration. Full recipe transfer from machine to machine. Load recipe from host and run on any machine. Innovative parallel activity machine design with Phi-Y movement pick-and-place. Low vibrations – no time wasted for motion settling. Simultaneous movement of chip and camera – no time wasted for image taking.

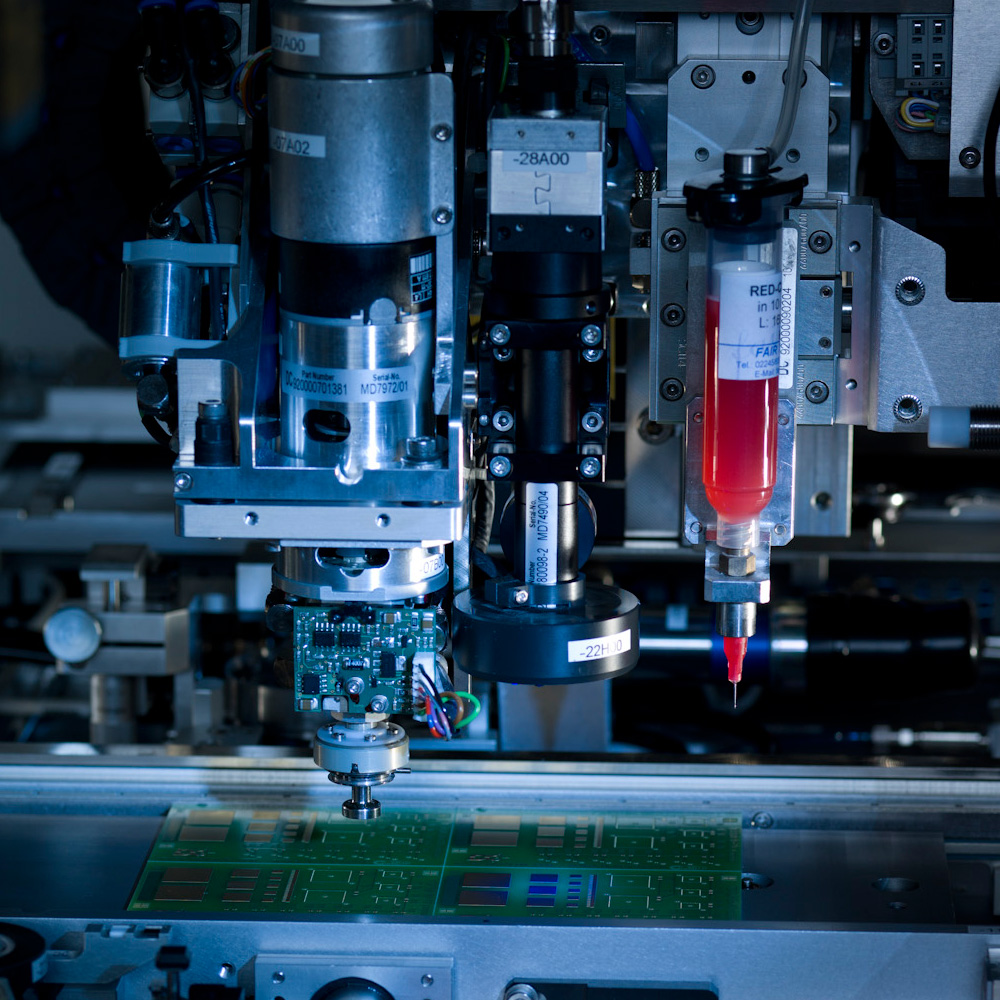

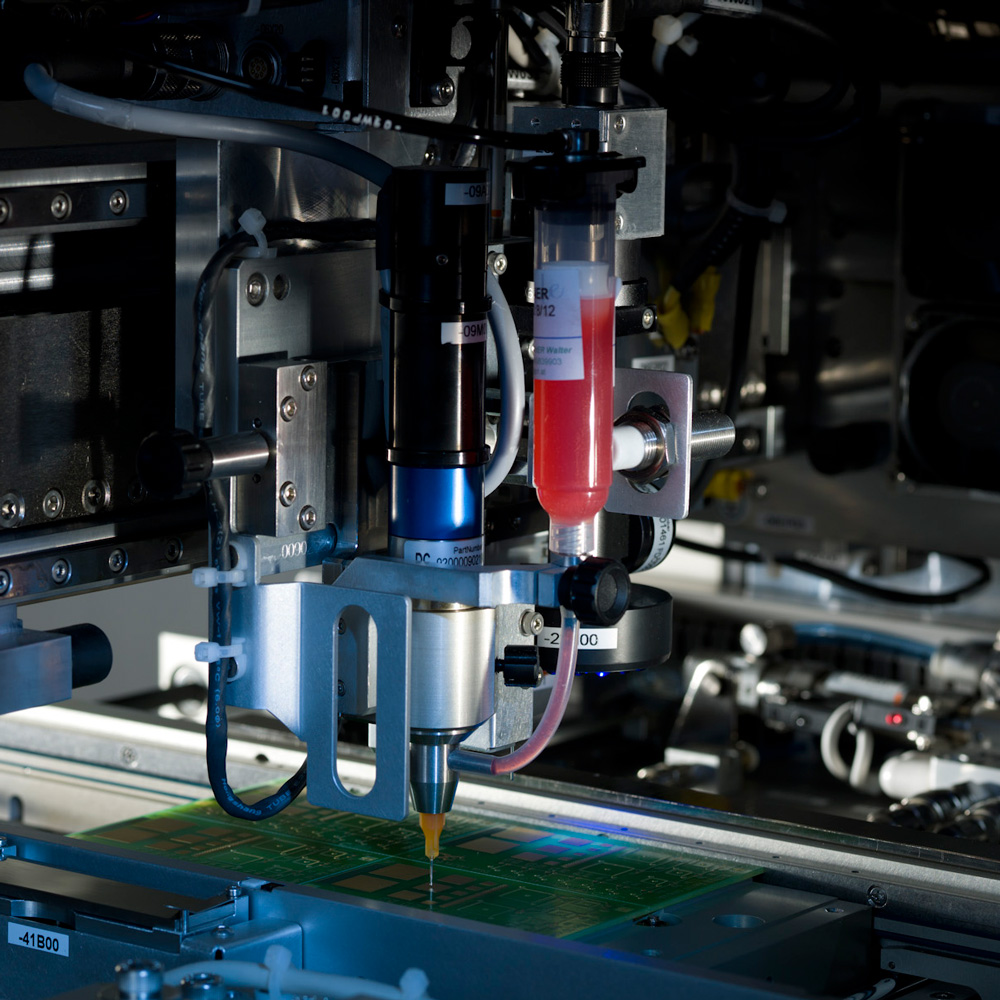

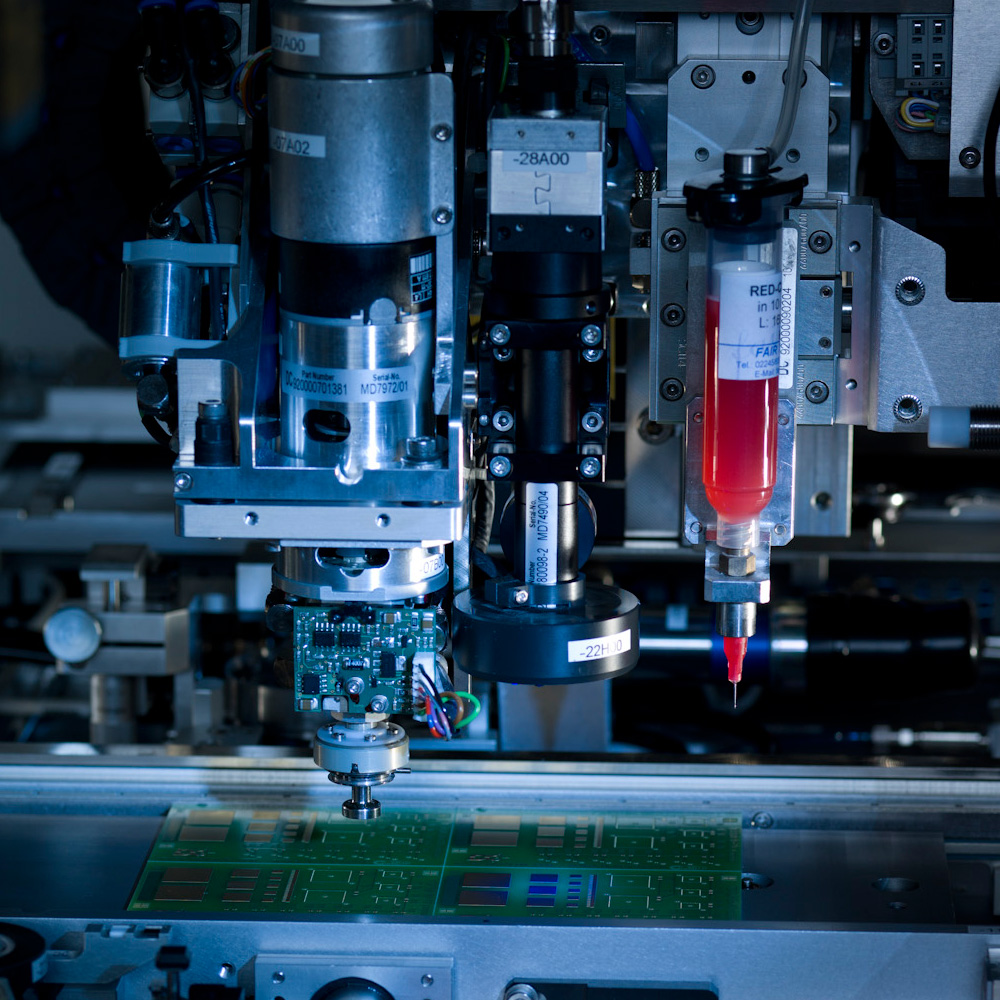

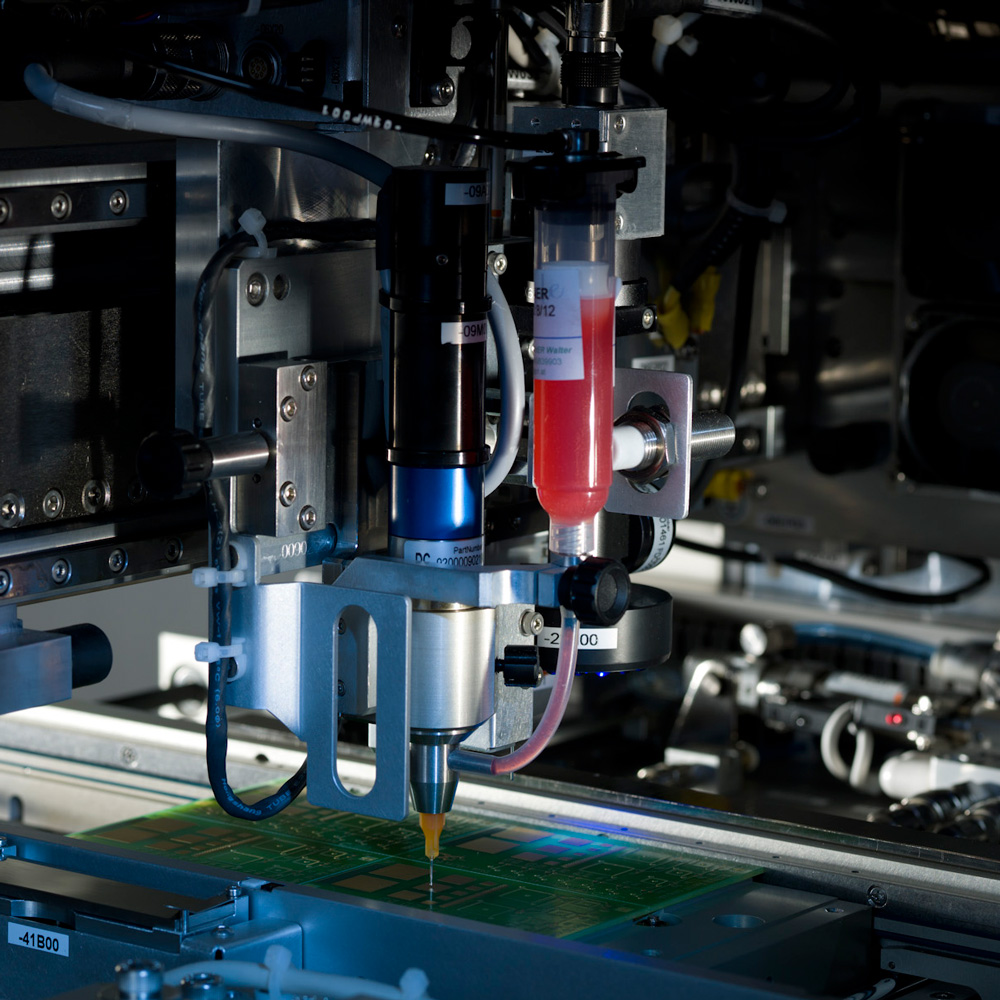

Equipped with integrated dispenser, 12” wafer handling, automatic tool changer, and application specific tooling, the 2200 evo is prepared for present and future processes and products.ĮSEC 2100 FC PLUS Esec as a renowned leader in providing die bonders for trouble free high quality mass production has integrated flip chip capability into its 2100 family of die bonders: Esec’s response to driving down the cost of flip chip technology. Test Handlers, Test interfaces, ManipulatorsĭATACON 2200 evo The 2200 evo high-accuracy multi-chip die bonder provides the ultimate flexibility for die attach as well as for flip chip applications.

IC Characterization and Functional Evaluation Test System. DC, RF, Resistivity probes and probe cards.

0 kommentar(er)

0 kommentar(er)